At TwentyOne Sugars , We are dedicated to producing high-quality sugar that exceeds industry standards. With a history of our sugar production, our experienced team has developed a reputation for excellence in the sugar manufacturing industry.

Our state-of-the-art facility is equipped with the latest technology and machinery, ensuring that our sugar is produced with precision and consistency. We source only the finest sugar cane from trusted local farmers, and our strict quality control measures ensure that every batch meets our high standards.

In addition to producing sugar, we are also committed to sustainability and environmental responsibility. We use renewable energy sources, implement efficient waste management practices, and make efforts to reduce our carbon footprint.

Our goal is to provide our customers with the best possible product, and our dedicated team is always working to improve and evolve our processes. With a commitment to quality, sustainability, and customer satisfaction, TwentyOne Sugars is the ideal choice for all your sugar needs.

The quality of the sugar manufactured at Twentyone Sugars is controlled by :-

We produce sugar of following grades :-

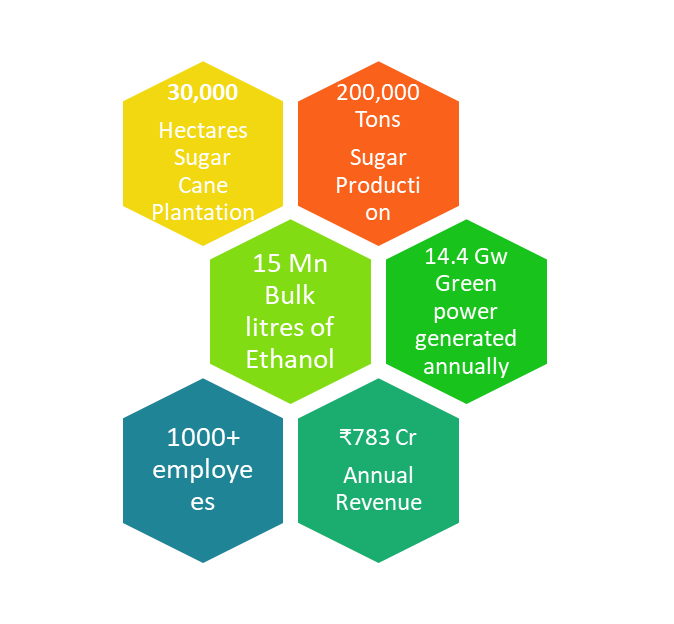

Our Strenghts :

Our Weakness :

Transforming the Intangible to Tangible

Global sugar consumption expected to moderate

Expected results: Rapid adoption, Growth and Profitability.

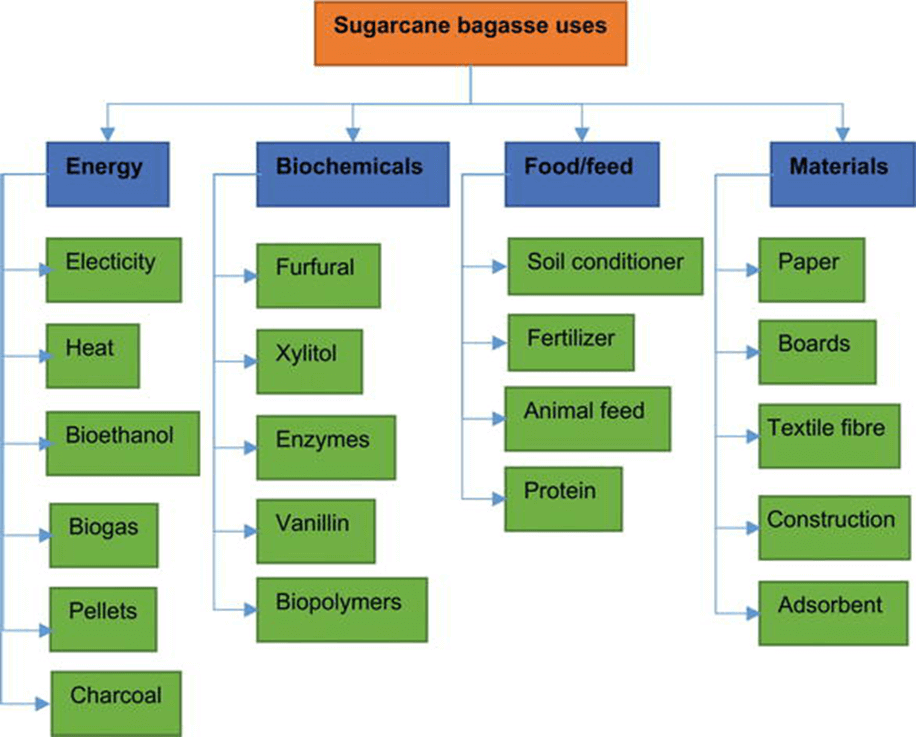

Product line

Sugar, Co-gen & Distillery

Legacy

Sugar Industry presence traditionally but not conventionally.

Key Points